Luminaire is constantly asking how we can elevate the art of coffee. Here are a few ways we've succeeded.

Working with tight space constraints and high temperature requirements, Luminaire designed the electronics with ChefSteps for Joule, the innovative sous vide circulator from ChefSteps. Equally powerful and half the volume as competing sous vide circulators, Joule combines power electronics, a thick film heater, a water circulator, Wi-Fi and Bluetooth modules in a tiny water-resistant package. From the start, Luminaire designed the electrical hardware to meet UL, CE, and cUL requirements and worked with ChefSteps engineers to integrate the electrical hardware into the rest of the product. Check it out here, https://www.chefsteps.com/joule.

When La Marzocco came to Luminaire to develop the electronics for the new Linea PB, we did more than design circuit boards: we analyzed La Marzocco’s product ecosystem and developed a modular architecture that allows La Marzocco to continuously innovate. After consolidating functional requirements for each machine, we developed electrical hardware that is reusable across product lines allowing new features to be quickly prototyped and incorporated into new products. We took the resulting designs from architecture to production, managing the manufacturing relationship.

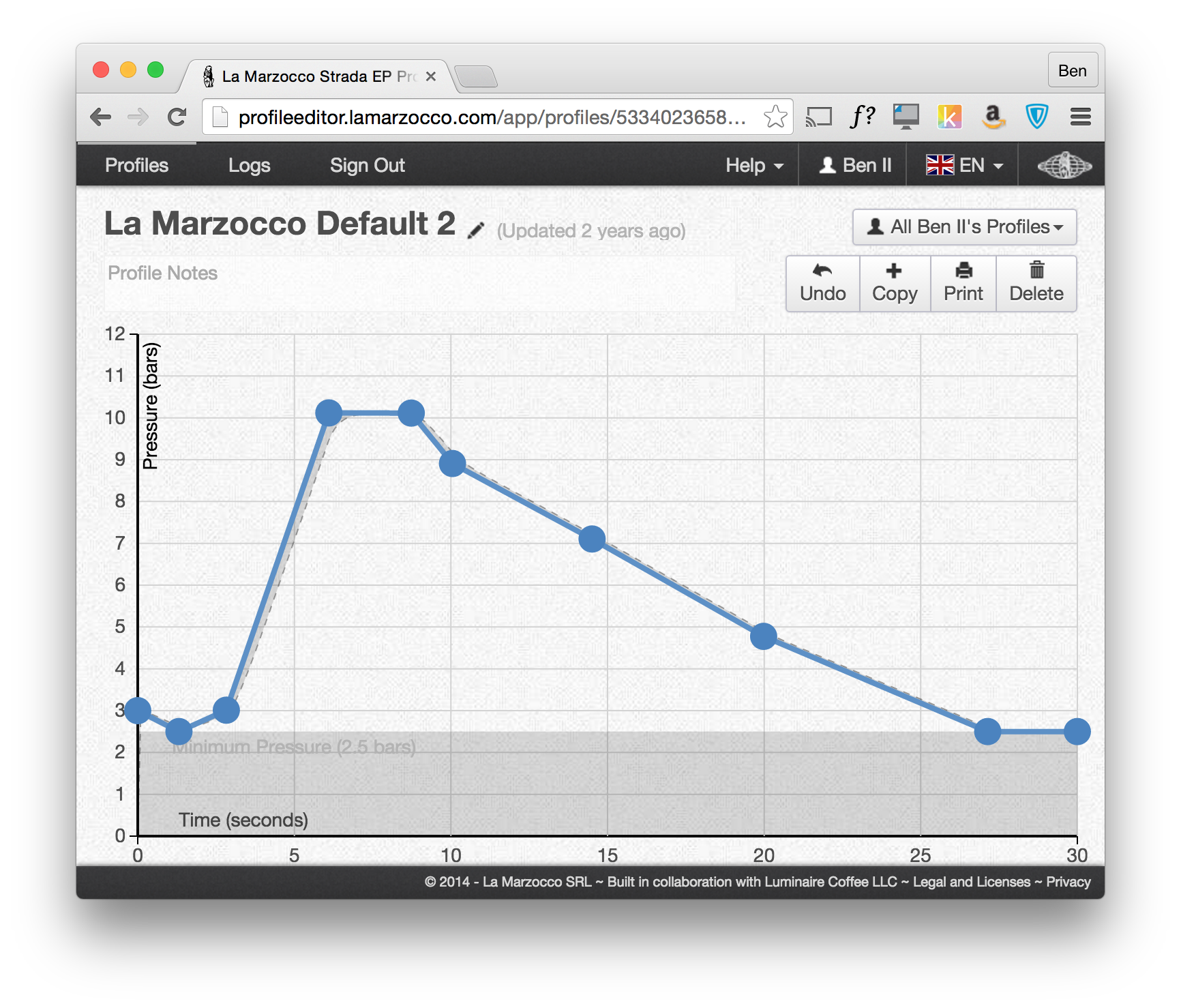

Luminaire worked with La Marzocco to design a modern and powerful web application that allows baristas around the world to create and share pressure profiles for their Strada EP. Luminaire was responsible for the design, implementation, deployment and maintenance of this web application. You can use the application here.

Timing a shot is an easy way to improve the quality and consistency of espresso, but surprisingly many high end espresso machines lack an automated timer. Luminaire designed the ShotTimer to measure the changes in the magnetic field of a solenoid when a shot is being pulled in order to provide an automatic, hands-off way to integrate timing into the brewing process. Engineered to work with any espresso machine, the ShotTimer does not require connection to proprietary components and is capable of running on a watch battery for years. The ShotTimer represents Luminaire's ability to focus on the details while understanding the big picture of what matters. You can purchase the ShotTimer here.

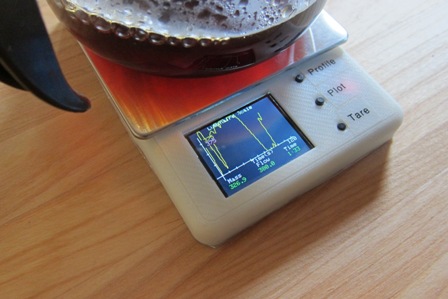

The scale is a standard component of any manual brewing setup, used to ensure consistency in the volume of water poured over the course of a brew. A skilled barista will use this tool to control the flow rate of water into the grounds, but a normal scale can only provide a limited picture of this important variable. Luminaire decided to take manual brewing to the next level by building a scale that not only measures the weight of a pour, but uses this data to provide a real-time graph of flow rate. After 2 days building a proof of concept prototype by taking apart an existing scale and adding custom circuitry and software to calculate flow rate, we validated the concept with local baristas and used their feedback to build a refined prototype. This prototype, built in just 2 weeks, added upgraded circuitry and smartphone integration. By displaying the flow history on a smartphone, we were able to quickly prototype interfaces and display styles.

The LB-1 combines state of the art engineering with the lofty goal of solving the barista's hot water dilemma. Using a proprietary heating technology combined with advanced control systems that leave PID in the dust, the LB-1 is able to heat water to any desired temperature within 2 seconds. Because there is no boiler, it never runs out of hot water. Combined with programmable flow control, the LB-1 is a pour-over brewing barista's best friend. While the LB-1 has not made it into mass production, it has proven to be a solid testing ground for advanced technology used throughout our products.

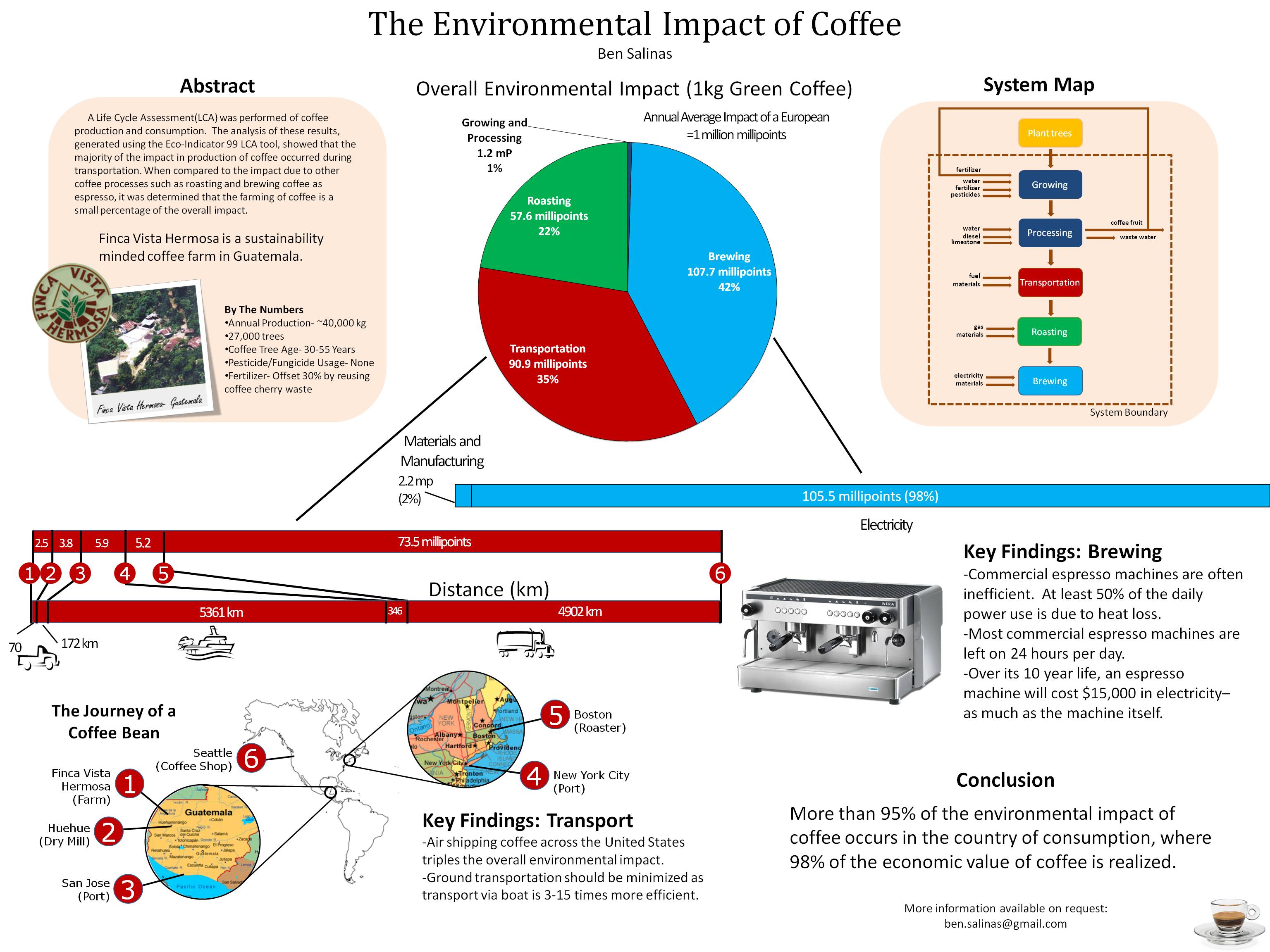

In order to quantify the environmental impact of on demand heating in coffee production, Luminaire team members performed a Life Cycle Assessment of Coffee Production. Data about coffee production was gathered by interviewing Edwin Martinez of Finca Vista Hermosa in Guatemala. To quantify the impact of the brewing process, energy data from espresso machines was gathered and an espresso machine was torn down to quantify the impact of the materials used in commercial espresso machines. The results showed that the majority of the environmental impact of this process occurred in the country of consumption. More details are available by downloading the poster and paper.